By: Foday Melvin Kamara

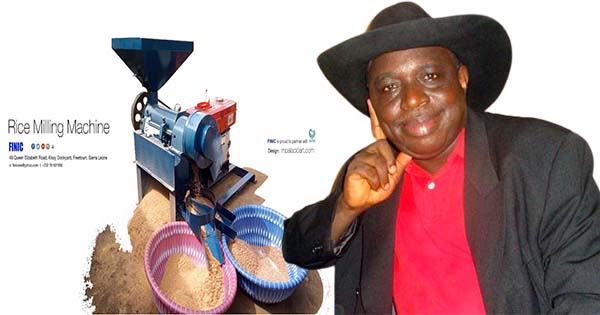

Managing Director of FINIC.

FINIC has existed for 24 years. Half way through that passage of time, we started experimentation with rice processing technologies. Today, we have reached a level beckoning us for celebrations.

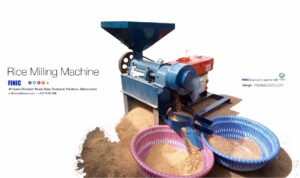

Rice parboilers, rice threshers, destoners and dryers moulded by our creative imagination and characterized by our conditions and circumstances in Africa, are today part of the epitome of excellence at FINIC. The FINIC model, Rice Milling Machine stands out with flying colours.

Please download the video if you can and experience how it deals with rough rice. If it deals with rough rice at such a speed, your imagination will not disappoint you that it is an easy work over with parboiled rice.

Here are few technical details about the FINIC Made Rice Mill:

1 – Capacity – 500Kg (10 bags) per hour.

2 – Power Source – a Diesel engine of 12 Horse Power. An electric motor of equivalent power can also be made to provide power

3- Sturdy construction and thus has long service life. We have had a case study where FINIC Rice Mill had served for over 14 years with exemplary performance.

4) Installation made easy as one does not need to apply concrete and use bolts & nuts of any sort.

5) Same machine dehulls coffee at a faster rate than rice

6 – Same machine degerms corn prior to corn flour making.

FINIC IS GOOD FOR AFRICA

Reach us at +232-76-601956 in Sierra Leone

Email: finicone@yahoo.com

In Ghana, contact us at +233 26 400 0480

Email: finicghana@gmail.com